The Rise of Auto Components Manufacturers: Driving Industry Trends

The automotive industry is a cornerstone of global economies, fostering innovation, job creation, and technological advancement. Within this arena, auto components manufacturers play a crucial role, providing the parts and systems necessary for vehicle assembly and performance. This article delves into the intricate world of auto components manufacturing, covering current trends, challenges, innovations, and the future outlook for this vital sector.

Understanding the Role of Auto Components Manufacturers

Auto components manufacturers are companies involved in the production of parts and systems used in the vehicle manufacturing process. Their products range from simple nuts and bolts to complex electronic systems. The efficiency and quality of these components directly affect the performance, safety, and reliability of vehicles on the road.

Types of Components Manufactured

- Mechanical Components: These include essential elements such as engines, transmissions, brakes, and suspensions that contribute to vehicle performance.

- Electrical Components: With the rise of electric vehicles, components such as batteries, wiring harnesses, and sensors have become increasingly important.

- Interior Parts: This category encompasses everything from seating and dashboards to lighting and climate control systems, enhancing passenger comfort and safety.

- Aerodynamic Elements: Components that improve a vehicle's aerodynamics, such as spoilers and air dams, are critical for efficiency and performance.

The Impact of Innovation on Auto Components Manufacturers

Innovation is at the heart of the automobile industry, and auto components manufacturers are continuously adapting to meet evolving consumer expectations and regulatory requirements.

Adoption of Advanced Technologies

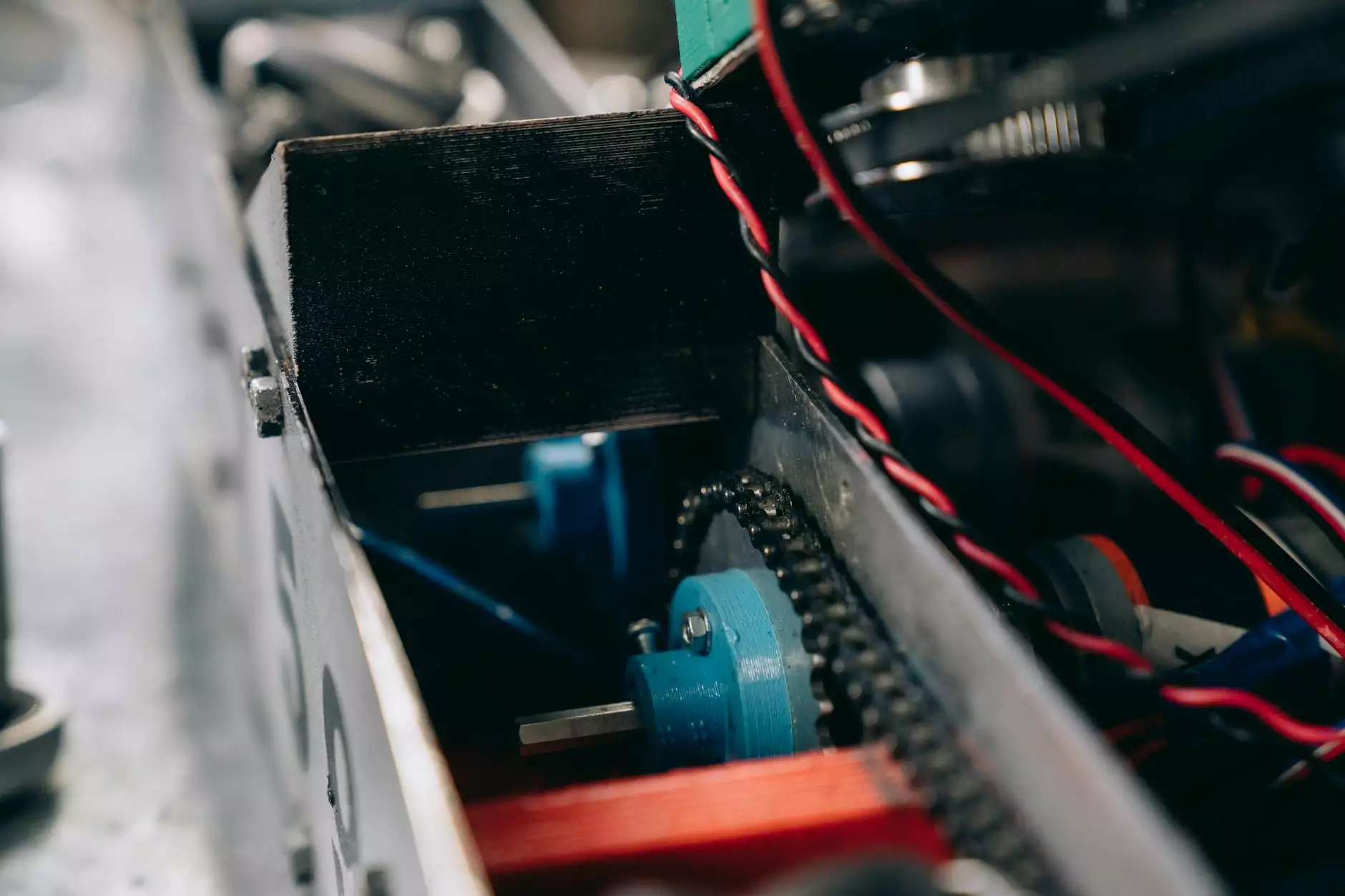

Technology has revolutionized the manufacturing processes in the automotive sector. From 3D printing for rapid prototyping to machine learning for quality control, auto component manufacturers are leveraging these advancements to enhance efficiency and reduce lead times.

The Role of Automation

Automation is increasingly becoming a standard in the production lines of auto components manufacturers. Robotics and smart manufacturing systems are being utilized to achieve higher precision and consistency, significantly lowering production costs while maintaining quality. This shift not only maximizes productivity but also addresses labor shortages faced by many manufacturing facilities today.

Emphasis on Sustainability

As the world moves towards greener technologies, sustainability has emerged as a priority for auto components manufacturers. Manufacturers are investing in eco-friendly materials and processes to minimize their environmental impact.

Recyclable Materials

Many manufacturers now aim to use recyclable materials in the production of auto parts. For instance, lightweight materials like aluminum and advanced polymers not only reduce vehicle weight, leading to better fuel efficiency but are also partially or fully recyclable at the end of their lifecycle.

Energy Efficiency in Production

Reducing energy consumption during manufacturing is another essential aspect. By optimizing processes and using energy-efficient machinery, manufacturers can decrease carbon emissions associated with production, contributing to a more sustainable automotive ecosystem.

Challenges Facing Auto Components Manufacturers

While the future looks promising for auto components manufacturers, they face several challenges that need to be addressed to maintain growth and competitiveness.

Global Supply Chain Disruptions

Recent events have highlighted vulnerabilities in global supply chains. Manufacturers have faced difficulties in sourcing raw materials, leading to increased costs and delays. Finding reliable suppliers and diversifying sourcing strategies are becoming essential to mitigate these risks.

Technological Adaptation

The rapid pace of technological change presents both opportunities and challenges. Manufacturers must stay ahead by investing in R&D to innovate and integrate new technologies into their production processes. Failure to adapt can lead to obsolescence in an increasingly competitive market.

Regulatory Compliance

With tightening emissions regulations and safety standards globally, auto components manufacturers must ensure compliance with various laws and guidelines. Navigating these regulations is crucial for maintaining market access and avoiding penalties.

The Future of Auto Components Manufacturers

The future of auto components manufacturers will be shaped by several key trends, including technological advancements, changing consumer preferences, and the push for sustainability.

Electrification and Hybrid Technologies

As electric vehicles (EVs) gain popularity, auto components manufacturers must pivot to offer parts that support these technologies, such as advanced battery systems, electric drivetrains, and regenerative braking systems. This shift opens up new markets and opportunities for growth.

Connected Vehicles and the Internet of Things (IoT)

The rise of connected vehicles presents exciting prospects for auto components manufacturers. Components that enable connectivity, such as sensors and infotainment systems, are becoming increasingly vital. Adapting to this tech-savvy consumer base requires manufacturers to integrate smart technologies into their offerings.

Collaboration and Partnerships

Collaborative efforts between automakers and component manufacturers are crucial for fostering innovation. By working together, companies can better align their goals, share knowledge, and develop cutting-edge technologies that propel the industry forward.

Conclusion

In summary, auto components manufacturers are critical players in the automotive industry, influencing everything from vehicle performance to safety and sustainability. As they continue to innovate and tackle challenges, these manufacturers not only contribute to the growth of the automotive market but are also central to its transformation towards a more sustainable, technologically advanced future. To thrive in this dynamic environment, embracing innovation, sustainability, and collaboration will be essential for all stakeholders involved.

Key Takeaways for Stakeholders

- Invest in Technology: Emphasize R&D to stay updated with technological advancements.

- Focus on Sustainability: Prioritize eco-friendly practices and materials.

- Diversify Supply Chains: Ensure flexibility in sourcing to mitigate risks.

- Collaborate: Foster partnerships with other manufacturers and tech firms.

By understanding these dynamics and strategically planning for the future, stakeholders within the auto components manufacturing sector can position themselves for success in an ever-evolving landscape.