The Advantages of China CNC Turning Parts in Modern Manufacturing

In the fast-paced world of manufacturing, businesses are continually seeking ways to enhance productivity, efficiency, and precision. One method that has revolutionized the industry is the use of China CNC turning parts. These components are integral to various applications across multiple sectors, from automotive to aerospace, and even in consumer products. This article will explore the benefits, processes, and factors to consider when sourcing these parts, ultimately helping your business thrive in a competitive environment.

What Are CNC Turning Parts?

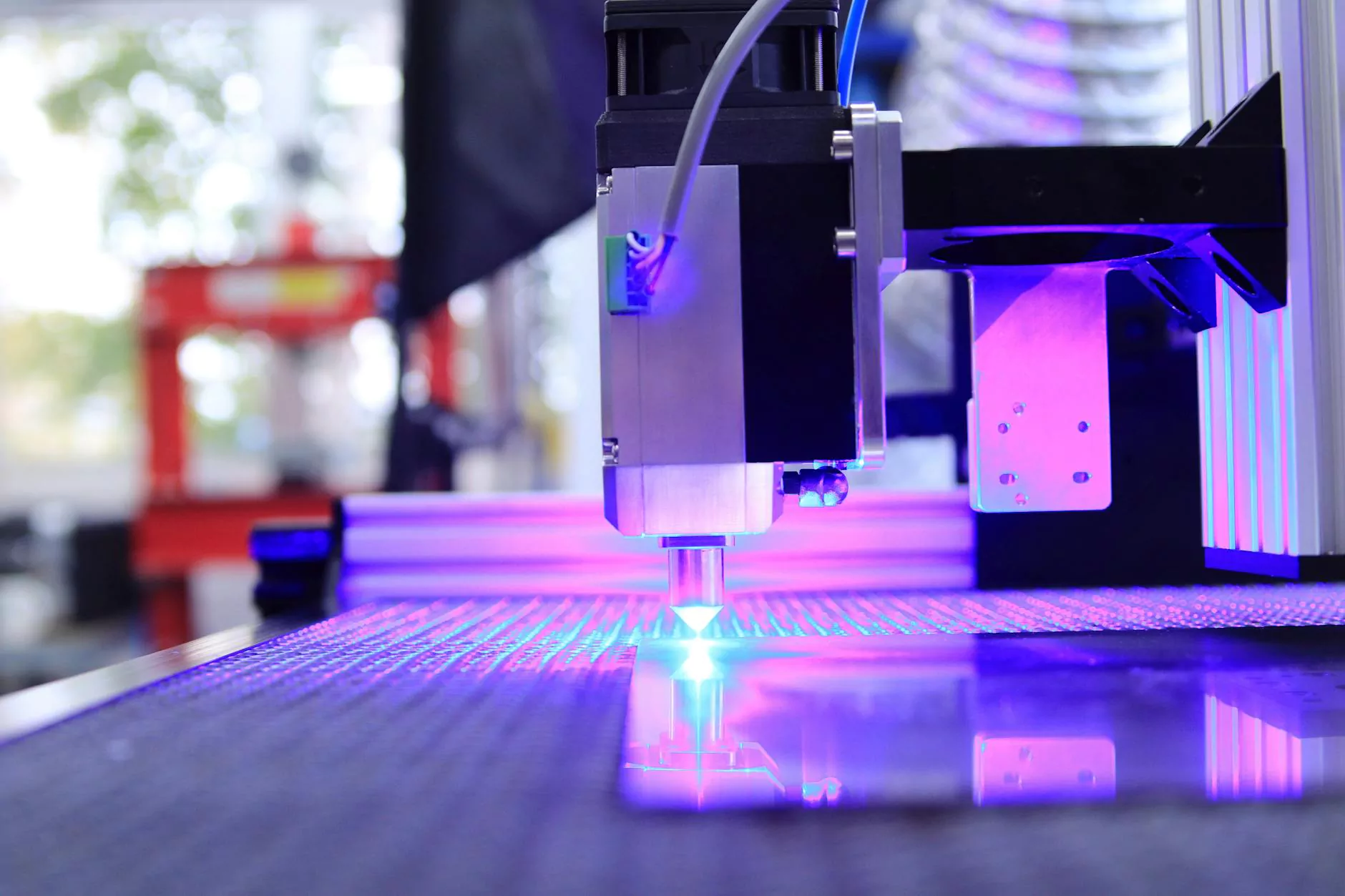

CNC, or Computer Numerical Control, refers to a manufacturing process that utilizes computerized controls to manage machine tools. In the case of turning parts, this process involves rotating the workpiece against a cutting tool to shape it into required designs and sizes. This technology enables manufacturers to produce complex shapes and intricate features that are difficult to achieve with traditional machining.

Why Choose China for CNC Turning Parts?

China has emerged as a leading hub for manufacturing, particularly in the realm of CNC machining. Here are several reasons why sourcing China CNC turning parts is advantageous:

- Cost Efficiency: The production costs in China tend to be significantly lower due to reduced labor costs and abundant raw materials. This allows businesses to save money without compromising quality.

- Advanced Technology: Chinese manufacturers invest heavily in modern CNC machinery and technology, ensuring high precision and quickly adaptable production capabilities.

- Skilled Workforce: China boasts a large pool of skilled technicians and engineers proficient in CNC machining and manufacturing processes.

- Scalability: Whether you need small-run prototypes or large-scale production, Chinese manufacturers can easily scale their operations to meet your demands.

- Robust Supply Chain: China’s comprehensive supply chain aids in the quick procurement of materials and components, reducing lead times significantly.

The CNC Turning Process Explained

The CNC turning process consists of several stages, each of which contributes to the final quality of the China CNC turning parts. Understanding this process is vital for manufacturers looking to improve their production line:

1. Design and CAD Modeling

The first step involves creating a detailed design using Computer-Aided Design (CAD) software. This allows for precise specifications of dimensions, tolerances, and materials.

2. Programming the CNC Machine

Once the design is complete, programmers use Computer-Aided Manufacturing (CAM) software to create a program that instructs the CNC machine on how to perform the required operations.

3. Material Preparation

Choosing the right raw material is crucial. Common materials used in turning parts include aluminum, stainless steel, brass, and plastic. The choice of material will depend on the application's requirements.

4. Machining Process

The machine prepares the workpiece for turning by positioning it securely in a chuck. The CNC machine then rotates the workpiece against the cutting tool, which precisely removes material according to the programmed specifications.

5. Quality Control

After machining, parts undergo rigorous quality control checks. This ensures that they meet the specified tolerances and standards, thus guaranteeing high reliability and performance.

Advantages of CNC Turning Parts

Utilizing China CNC turning parts offers numerous benefits to manufacturers:

- High Precision: CNC machining delivers unmatched precision, crucial for parts that require exact specifications.

- Consistency and Reproducibility: Once the machining process is programmed, it can reproduce parts with consistent quality, reducing the variation often seen in manual machining.

- Complex Shapes and Features: CNC turning allows for the production of complex geometries and features which would be challenging, if not impossible, to achieve with conventional methods.

- Reduced Waste: Precision machining significantly reduces material waste by ensuring that only the necessary amount of material is removed.

- Speed: CNC turning is quicker than traditional methods, resulting in faster turnaround times for parts production.

Choosing the Right Manufacturer for China CNC Turning Parts

While the benefits are clear, choosing a reliable supplier is crucial to the success of your manufacturing operation. Consider the following factors:

1. Quality Certifications

Ensure that the manufacturer adheres to quality management standards such as ISO 9001. This indicates a commitment to quality throughout the manufacturing process.

2. Experience and Expertise

Look for manufacturers with a strong track record and experience in producing China CNC turning parts for your industry.

3. Capabilities and Technology

Assess the technological capabilities, including the types of CNC machines and tools they utilize. Advanced equipment can enhance production quality and efficiency.

4. Customer Support and Communication

Strong communication and responsive customer support are vital for addressing any concerns during production. Choose a supplier that values transparency and collaboration.

5. Pricing and Payment Terms

While cost is a significant factor, ensure that pricing reflects the quality of products offered. Compare multiple manufacturers to find the best value.

Market Trends in CNC Machining

The CNC machining industry is dynamic and subject to evolving trends. Here are some current trends affecting China CNC turning parts:

- Automation and Robotics: Increased automation lowers labor costs and improves production speeds. Manufacturers adopting robotics see significant efficiency gains.

- 3D Printing Integration: Many companies are beginning to combine CNC machining with 3D printing to create intricate designs and prototypes quickly.

- Focus on Sustainability: Manufacturers are increasingly focusing on sustainable practices, including reducing waste and utilizing eco-friendly materials.

- Customization: There is a growing demand for customized machining services, allowing businesses to produce tailored parts that meet specific needs.

Conclusion

In conclusion, the use of China CNC turning parts can provide businesses with significant advantages in terms of cost, precision, and efficiency. By understanding the machining process, evaluating potential suppliers, and staying updated on industry trends, companies can effectively leverage these components to enhance their production capabilities and maintain a competitive edge.

As the demand for precision parts continues to rise, the role of CNC machining in manufacturing will only expand. By partnering with reputable manufacturers in China, businesses can ensure they have access to the quality and expertise needed to thrive in today's market.