Revolutionizing Business Efficiency with Cutting-Edge 3D Printing in Road Sweeper Trucks

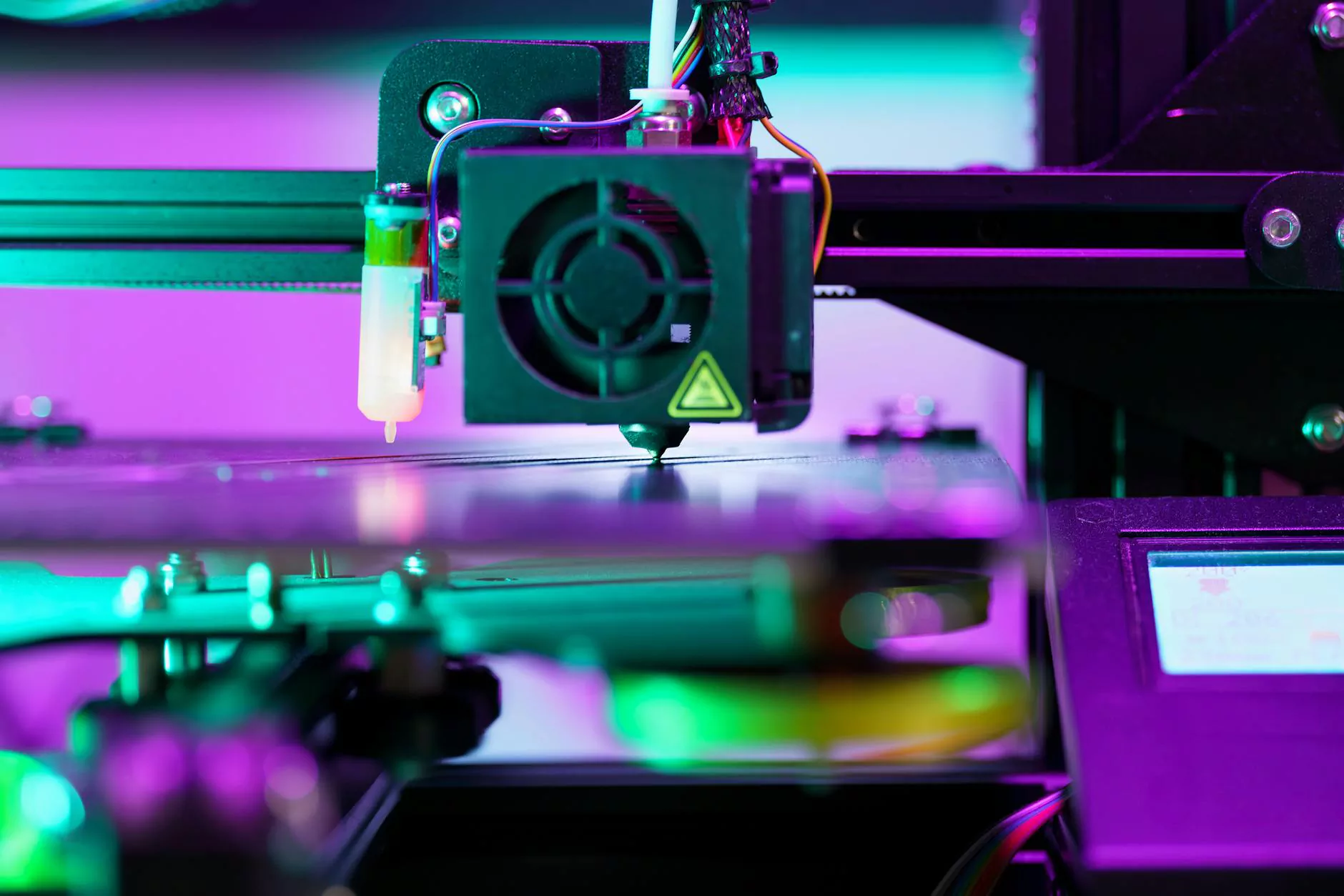

In the rapidly evolving landscape of industrial manufacturing, innovation drives competitiveness and growth. One of the most transformative technologies shaping the future of manufacturing is 3D printing. Particularly within the niche of road sweeper trucks, 3D printing offers unparalleled advantages in design flexibility, cost reduction, and maintenance efficiency. This comprehensive exploration delves into how businesses, especially those specializing in construction, municipal services, and waste management, are leveraging 3D printing to revolutionize their fleet of road sweeper trucks.

Understanding the Role of 3D Printing in Modern Manufacturing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital models through successive layering of materials. This technology contrasts sharply with traditional subtractive manufacturing, providing several benefits that are particularly advantageous in the production of complex components such as those used in road sweeper trucks.

- Design Flexibility: 3D printing allows for the creation of intricate, custom-designed parts that are difficult or impossible to produce using conventional methods.

- Cost-Effective Small Batch Production: It reduces the need for expensive tooling and molds, especially beneficial for limited or prototype runs.

- Rapid Prototyping and Development: Businesses can develop and test new parts swiftly, accelerating the product innovation cycle.

- On-Demand Manufacturing: Replacement parts can be produced quickly on-site, minimizing downtime and logistic costs.

- Sustainability: Additive manufacturing significantly reduces waste material, aligning with eco-friendly business practices.

Advantages of 3D Printing in the Production of Road Sweeper Trucks

The application of 3D printing technology in road sweeper trucks addresses several key challenges faced by manufacturers, operators, and maintenance teams. Here are some of the predominant benefits:

1. Customization and Complex Geometry

Every city or municipality has unique sanitation requirements, making customization fundamental. 3D printing enables the creation of tailored components such as specialized dust suppressors, adjustable brushes, and unique hopper covers. The technology allows for complex geometries that optimize airflow, debris collection efficiency, and vehicle aerodynamics, thereby enhancing overall operational performance.

2. Lightweight Components for Improved Efficiency

Reducing the weight of road sweeper trucks contributes directly to fuel savings and increased payload capacity. 3D-printed components made from advanced polymers or lightweight metals such as aluminum alloys can significantly decrease the overall weight without compromising strength or durability, leading to lower operational costs and a reduced carbon footprint.

3. Accelerated Maintenance and Spare Parts Production

In urgent maintenance scenarios, the ability to 3D print spare parts on demand ensures minimal downtime. Replacement parts that are traditionally expensive and lengthy to produce can now be quickly manufactured on-site, ensuring that fleet operations remain uninterrupted and efficiency is maximized.

4. Cost Savings and Resource Optimization

By reducing the need for inventory storage and decreasing material waste, 3D printing drives down manufacturing costs. Additionally, the ability to produce parts with minimal tooling allows smaller firms and municipal authorities to access high-quality components without exorbitant investment.

Innovative Applications of 3D Printing in Road Sweeper Trucks

The scope of 3D printing in the context of road sweeper trucks extends across multiple domains, including design, manufacturing, and maintenance. Here are some notable applications shaping the future of these essential municipal vehicles:

Design Optimization and Rapid Prototyping

Innovative design iterations can be rapidly developed and tested, leading to the creation of more efficient and reliable road sweeper trucks. For example, complex fluid dynamics models for dust suppression systems and debris handling mechanisms can be materialized and validated quickly with 3D printing.

Development of Wear-Resistant Parts

Components subjected to extreme wear and tear, such as brushes, blades, and suction nozzles, can be manufactured with specialized materials using 3D printing. This enhances longevity, reduces replacement frequency, and optimizes maintenance budgets.

Innovative Filters and Dust Extraction Systems

Custom filters and dust extraction components fashioned through 3D printing provide tailored solutions for different types of dust and debris, ensuring cleaner and healthier urban environments. The ability to test various designs expediently accelerates innovation in air quality management.

On-Board Sensors and Smart Components

The integration of IoT-driven sensors into 3D-printed housings allows for real-time monitoring of vehicle performance, providing feedback loops for preventive maintenance and operational efficiency. This fusion of technologies propels road sweeper trucks into the era of smart, data-driven municipal vehicles.

Challenges and Future of 3D Printing in Road Sweeper Trucks

While the advantages are compelling, certain challenges still temper the widespread adoption of 3D printing technology in this segment.

- Material Limitations: While composite and metal 3D printing have advanced, some materials still lack the durability needed for heavy-duty applications.

- Regulatory and Safety Standards: Ensuring that 3D-printed components meet industry safety and quality standards is crucial for widespread acceptance.

- Production Speed for Large Components: Larger parts may still take considerable time to print, although ongoing innovations are reducing these durations.

- Cost of Advanced 3D Printing Equipment: High initial investments can be a barrier for small to medium-sized businesses.

Looking forward, advancements in materials science, printing speeds, and post-processing techniques promise to mitigate these hurdles. Innovations like multi-material printing and hybrid manufacturing processes will expand the scope and capabilities of 3D printing in the road sweeper trucks industry.

How Businesses Can Leverage 3D Printing for Competitive Advantage

Businesses aiming to stay ahead in the competitive field of municipal and industrial vehicle manufacturing should consider integrating 3D printing into their strategic operations. Here’s how:

1. Invest in R&D and Prototype Development

By leveraging 3D printing for rapid prototyping, companies can innovate faster, testing new design ideas without significant upfront costs and providing custom solutions tailored to customer needs.

2. Develop a Digital Inventory for Spare Parts

Maintaining a digital repository of component models allows for just-in-time manufacturing, minimizing inventory costs and ensuring quick service delivery.

3. Collaborate with Material and Technology Experts

Partnering with material science companies and 3D printing specialists can open avenues for developing specialized parts suited for demanding applications like those found in road sweeper trucks.

4. Sustainability as a Core Business Practice

Adopting 3D printing aligns with greener manufacturing principles, reducing waste and energy consumption, which appeals to environmentally conscious consumers and regulatory bodies.

Conclusion: A New Era of Innovation in Road Sweeper Trucks

The integration of 3D printing technology into the manufacturing, maintenance, and customization of road sweeper trucks signals a transformative shift in this vital industry. With benefits spanning from enhanced design flexibility, weight reduction, cost savings, to faster parts production, 3D printing paves the way for smarter, more efficient, and environmentally friendly fleet management.

As companies like ceksansweepers.com continue to innovate within the 3D Printing category, they set new standards for excellence and sustainability in municipal and industrial sanitation solutions. Embracing this cutting-edge technology today ensures a resilient, forward-looking business equipped to meet the challenges of tomorrow’s urban environments.